- A masterpiece to be proud of

- A product line that contains hundreds of varieties of electric cable alone. Precision electronic components. An infinite variety of customer needs. To bring this all together, we have pro-actively created a state-of-the-art and highly flexible development, production, and distribution system with manufacturing and sales in both Japan and mainland China. For today’s information society where speed is life, we have an international product management system that uses an enhanced network with operations built around the keyword: “reliable.”

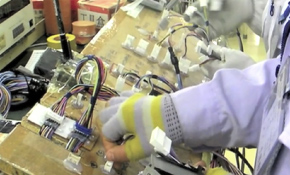

This picture depicts a harness which is a core component of many key products such as industrial robots. We also take pride in our longevity and financial performance: we celebrated our 70th anniversary in 2017 and suffered an annual loss only once in all those years.

- Thoughts of a technician

- Hokko Corporation spares no effort, every day, to exceed the expectations of our customers with the highest quality products, no matter what their business or how large or small their demand. We can submit the best possible options because we simplify our work processes, perform verifications a the design drawing level, and painstakingly eliminate previously overlooked or undiscovered inefficiencies in ways that our competitors find it difficult or impossible to replicate. It may be only a small part, buried inside other components and never touched or seen by the customer. Nevertheless, we take pride in making and handling every single part with the high quality and high value added our customers want, expect, deserve, and appreciate.

Manufacturing process

- 1

- Cutting electrical wire

- Here we are cutting electrical wire to the desired length

- 2

- Crimping terminal

- Here we are crimping a terminal to a wire

- 3

- Inserting a connector

- Here we are inserting a crimped wire into a connector

- 4

- Joint

- Joining a large number of electric wires together with bands so that the wires remain neat and orderly

- 5

- Inspection

- We conduct various inspections to check for such things as external appearance, correct electrical conduction, continuity, appropriate color, etc.

- 6

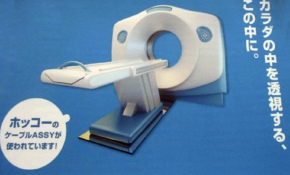

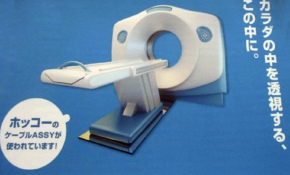

- In what kind of applications are our products used?

- Our harnesses alone are used in many industrial machinery applications such as medical equipment and robots, as well as in the automobile, game machines, and vending machine industries

Administrative support of manufacturing

- The new sales office

- We moved our Sales Division Office of Kyoto Branch on Monday, November 26, 2018. The new address is: #3040 3rd Floor of Life Plaza Nishioji-Shijo Bldg. The building is in the northeast corner of Nishioji Takatuji intersection. It is 5 minutes on foot to the north from the current Kyoto Branch Office. With improvement in the workplace, we refreshed ourselves at the start of the new office. All of us in Kyoto Branch unite our efforts in promotion of the active production for further growth. We appreciate your continued support.

- Production control department

- We carry out production planning, subcontracting management, parts procurement, cost control, and other functions here

- Inspection, packing, shipping department

- Final inspection, packing, and shipping are performed here

- Manufacturing division

- Production control, inspection, packing, and shipping is performed in a separate facility from the sales department

▲